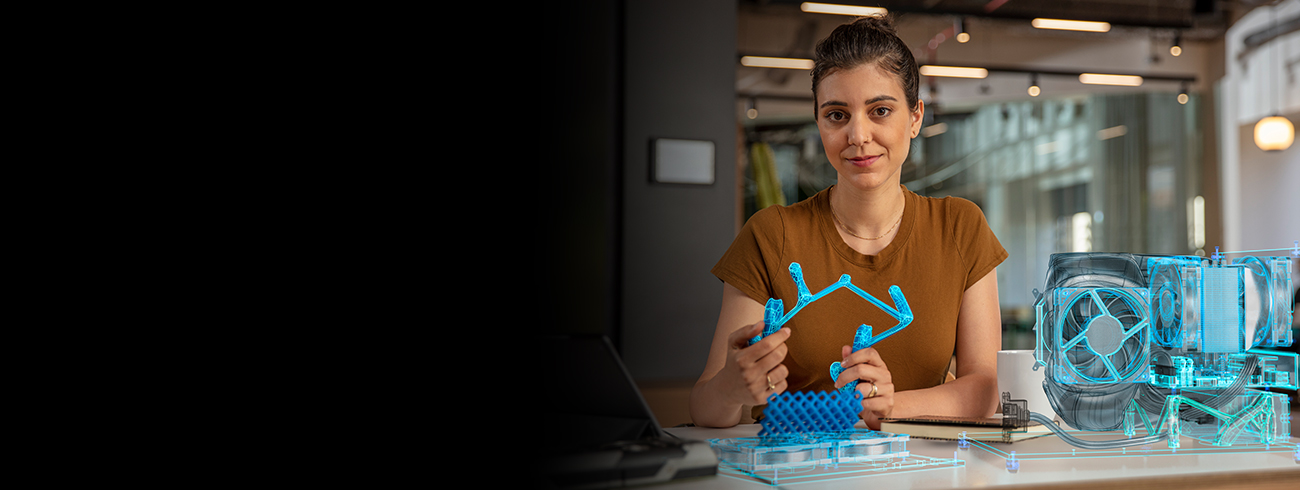

PDM/PLM for Connected Product Development

Agile Supply Chain. Streamlined Process.

Remove development roadblocks to help you deliver better products faster.

What is Connected Product Development?

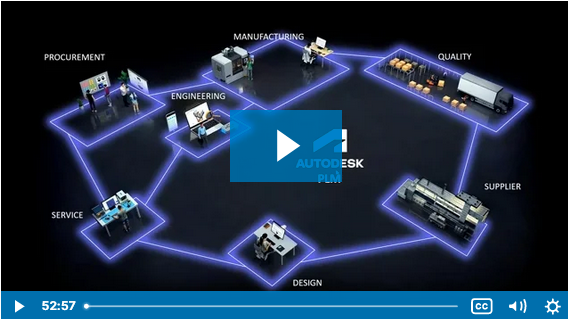

Connected Product Development is the process of unifying your teams, tools, and data to accelerate innovation, reduce rework, and ensure product quality. It bridges the gap between engineering, manufacturing, and operations through integrated systems like PDM and PLM.

Why It Matters

- Break down silos between design, productions, and supply chain

- Gain real-time access to accurate design and BOM data

- Reduce errors caused by disconnected systems

- Support compliance and traceability throughout the product lifecycle

- Improve engineering collaboration across locations and teams

Real-World Use Cases

- Boost team productivity with centralized data and cloud-based PLM. Connected dispersed teams and reduce rework across CAD platforms.

- Make smarter decisions earlier by sharing real-time cost and material data across stakeholders. Minimize delays, scrap, and warranty issues.

- Enhance supply chain agility with supplier portal access. Streamline quoting, improve visibility, and speed up response time.

/connected-product-development@2x.jpg?width=600&height=350&name=connected-product-development@2x.jpg)

Software for PDM/PLM for Connected Product Development

Frequently Asked Questions

Have Questions? We are here to help

How is connected product development different from traditional product development?

Connected product development unifies design, engineering, manufacturing, and supply chain data across teams and systems in real time. Traditional product development often relies on disconnected tools and manual processes, which can lead to delays, errors, and data silos.

Can connected product development be implemented gradually?

Yes! Many organizations start by connecting specific tools (like PDM and ERP systems) or teams, then expand to integrate broader processes and data flows over time. We help build a scalable roadmap that fits your pace and goals.

What kind of systems can be integrated in a connected product development approach?

Common integrations include CAD, PDM, PLM, ERP, and collaboration platforms. We work with your existing tools, like Autodesk Vault, Fusion, or other platforms, to create a connected environment tailored to your needs.

What are the signs that our current product development process isn't connected enough?

Frequent rework, miscommunication between departments, version control issues, and delays in approvals or releases are common indicators. A connected approach helps eliminate these inefficiencies and improves overall visibility and control.

How do PDM and PLM systems improve BOM management?

These systems allow teams to build, sync, and update bills of materials from multi-CAD sources in real time, reducing errors and improving productivity.

Helpful Resources

Latest Posts

Customer Reviews

Kendred is great, I'm very appreciative of his patience and insight regarding upgrading our vault server.

Great experience, people were knowledgeable and accommodating. [They] were organized and carried out the work effectively.